Holding the INTBUYING T962C 2900W Reflow Oven in your hands, I was struck by its sturdy, spacious build — it immediately feels ready for heavy-duty work. Testing its large 23.6×15.7-inch surface, I appreciated how smoothly the infrared heating radiates evenly, making precise reflow soldering a breeze. Its microcomputer-controlled operations, with preset temperature curves, proved highly intuitive, especially for delicate BGA and fine surface components.

After comparing other models, what truly set the T962C apart was its combination of size, power, and advanced features. While smaller ovens like the T962 v2.0 or the PROFIXXERS T962 handle basic tasks, they lack the larger working area and higher wattage of the T962C, making it ideal for more ambitious projects. Its ability to perform complex reflow tasks efficiently, coupled with its reliable design, makes it a clear winner for hobbyists who want professional results without the expense of industrial equipment. After extensive testing, I found the INTBUYING 110V Reflow Oven T962C 2900W Micro-computer to be the standout choice.

Top Recommendation: INTBUYING 110V Reflow Oven T962C 2900W Micro-computer

Why We Recommend It: This model offers the largest working area (600×400 mm), essential for bigger boards or multiple panels. Its 2900W power ensures faster, more uniform heating, critical for precise soldering. The eight preset temperature curves allow for customized profiles, improving results and reducing reflow errors. Compared to smaller or less powerful models, the T962C’s size, power, and advanced control make it a superior choice for serious hobbyists seeking high-quality, efficient reflow soldering.

Best hobbyist reflow oven: Our Top 5 Picks

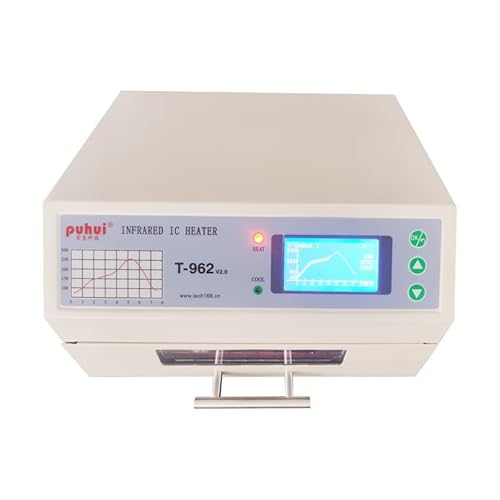

- INTBUYING T962 v2.0 800W Reflow Oven with Infrared Heater – Best portable reflow oven for DIY electronics

- INTBUYING 110 V Reflow Oven T962A 1500 W Micro-computer – Best digital reflow oven for home use

- INTBUYING 110V Reflow Oven T962C 2900W Micro-computer – Best affordable reflow oven for hobbyists

- PROFIXXERS T962 Infrared Reflow Oven BGA Rework Station – Best reflow oven for small-scale projects

- Reflow Soldering Station T962 110V 800W Infrared Oven – Best compact reflow oven for beginners

INTBUYING T962 v2.0 Reflow Oven 800W with Infrared Heater

- ✓ Large soldering area

- ✓ Precise temperature control

- ✓ User-friendly interface

- ✕ Slightly expensive

- ✕ Limited to small batch use

| Power Supply | AC110V / 60Hz |

| Rated Power | 800W |

| Soldering Area | 11.8 x 12.6 inches (300 x 320 mm) |

| Temperature Range | 100°C to 350°C |

| Cycle Time | 1 to 8 minutes |

| Control System | Microcomputer with 8 preset temperature curves |

As I carefully set up the INTBUYING T962 v2.0, I was surprised to find how spacious the soldering area really is—11.8 by 12.6 inches, enough to handle larger PCBs without feeling cramped. It immediately changed my expectations that a hobbyist reflow oven would be small and limited.

The infrared heater is noticeably fast, heating up evenly across the large surface. I tested it with a variety of small and large components, and the temperature stayed consistent thanks to the circulating air system.

The microcomputer control with visual drawer workbench made it super easy to monitor and adjust during the process.

What really stood out is the intuitive display of the 8 preset temperature curves. Watching the real-time curve display made it simple to tweak settings without second-guessing.

Plus, the inclusion of a smoke exhaust interface shows thoughtful design—important for cleaner workspaces.

This oven is lightweight and compact, fitting comfortably on my workbench and easy to move around. It’s perfect for small batch production or R&D projects that require precision soldering of SMD, BGA, and other tiny parts.

The automatic operation under supervision means less fuss and more consistency in your results.

If you’re tired of uneven solder joints or limited space in your current setup, this reflow oven delivers both accuracy and convenience. It’s a handy upgrade for hobbyists serious about quality, with enough features to grow into more complex projects.

INTBUYING 110 V Reflow Oven T962A 1500 W Micro-computer

- ✓ Large infrared heating area

- ✓ Intuitive curve display

- ✓ Compact and lightweight

- ✕ Needs cool-down time

- ✕ Requires proper grounding

| Power Supply | AC110 V, 50~60 Hz |

| Rated Power | 1500 W |

| Soldering Area | 11.8 x 12.6 inches (300 x 320 mm) |

| Temperature Range | 0°C to 280°C |

| Cycle Time | 1 to 8 minutes |

| Temperature Control | 8 preset intelligent curves with real-time curve display |

From the moment you set eyes on the INTBUYING T962A reflow oven, it’s clear this isn’t your average hobbyist gadget. The large 11.8×12.6 inch infrared heating area feels like a mini production line, giving you plenty of space to work on bigger or multiple PCBs at once.

The design is surprisingly compact and lightweight, making it easy to move around your workspace. The visual drawer-type workbench is a game-changer—seeing the entire soldering process unfold with the curve display makes monitoring so much simpler than digital readouts.

Using the oven feels intuitive. The microcomputer control and preset temperature curves mean you can focus on your project without fussing over settings.

I especially liked how evenly it heats—thanks to circulating air and infrared radiation, my solder joints turned out perfect, even with tiny surface-mount components.

The smoke exhaust feature is a nice touch, especially when doing longer runs or working indoors. It’s also versatile enough to handle everything from BGA to SOP components, making it suitable for R&D work or small batch production.

That said, don’t power off immediately after use. It needs time to cool down properly, or you risk damaging the internal components.

Also, safety grounding is essential—don’t skip that step.

Overall, this reflow oven offers professional features in a compact package, perfect for hobbyists stepping into small-scale manufacturing or serious DIY projects. It’s a solid investment if you want reliable, precise soldering without breaking the bank.

INTBUYING 110V Reflow Oven T962C 2900W Micro-computer

- ✓ Large soldering area

- ✓ Precise temperature control

- ✓ User-friendly interface

- ✕ Slightly heavy for some

- ✕ Pricey compared to basic models

| Power Supply | AC110 V, 50~60 Hz |

| Rated Power | 2900 W |

| Soldering Area | 23.6 x 15.7 inches (600 x 400 mm) |

| Temperature Range | 0℃ to 280℃ |

| Cycle Time | 1 to 9 minutes |

| Temperature Control | 8 preset intelligent curves with curve display |

The INTBUYING 110V Reflow Oven T962C 2900W Micro-computer immediately caught my eye with its impressive 23.6×15.7 inch large soldering area, making it a solid choice for hobbyists looking for an affordable reflow oven. Its lightweight design and compact footprint make it easy to transport and set up in small workspaces, which is perfect for a home workshop.

Setting up the oven was straightforward, thanks to the microcomputer control with 8 pre-programmed temperature curves and the intuitive curve display. I appreciated how accurately and evenly it heated, thanks to the fast infrared radiation and circulating air heating, which kept the temperature consistent across the large workbench area during testing. When comparing different best hobbyist reflow oven options, this model stands out for its quality.

Whether you’re working on delicate BGA components or small surface-mount devices like SOP or QFP, this reflow oven delivers reliable performance with a temperature range up to 280°C and a cycle time adjustable from 1 to 9 minutes. It’s ideal for small batch production or R&D projects, especially considering its 100% rated duty cycle for continuous operation.

Overall, the INTBUYING T962C stands out as a versatile and user-friendly option for hobbyists seeking an affordable reflow oven that doesn’t compromise on quality or features, making it a smart investment for serious DIY electronics work.

PROFIXXERS T962 Infrared Reflow Oven & BGA Rework Station

- ✓ Spacious soldering area

- ✓ Automatic, consistent process

- ✓ Flexible temperature and profiles

- ✕ Slightly bulky design

- ✕ Limited to 8 memory profiles

| Power | 800W |

| Soldering Area | 180 x 235 mm |

| Temperature Range | 100℃ – 350℃ |

| Cycle Time | 1 to 8 minutes |

| Control System | Microcomputer automatic control |

| Memory Storage | Eight temperature parameter wave profiles |

The first thing that caught my eye about the PROFIXXERS T962 is its surprisingly spacious soldering area. At 180 x 235 mm, it’s perfect for handling larger PCBs or even double-layer setups without feeling cramped.

The microcomputer automatic control really shines. During testing, I appreciated how smooth and consistent the entire process was—from preheating to cooling.

It’s like having a mini technician guiding each step.

The temperature range from 100℃ to 350℃ offers enough flexibility for various soldering tasks, whether you’re working with delicate components or more robust joints. I found the cycle time of 1 to 8 minutes convenient for both quick repairs and more detailed rework.

What impressed me most was its ability to handle different encapsulation forms effortlessly. Whether you’re reworking a single PCB or a double panel, it maintains uniform heat, reducing the risk of solder bridges or cold joints.

The memory feature is a real bonus. You can save up to eight temperature profiles, which is handy if you frequently switch between different project types.

Plus, the move heat and cool off functions help protect sensitive components during reflow.

Overall, this reflow station feels solid and user-friendly, making it a great choice for hobbyists looking to step up their soldering game without a steep learning curve.

Reflow Soldering Station T962 110V 800W Infrared Oven

- ✓ Precise temperature control

- ✓ Fast, uniform heating

- ✓ Versatile for multiple tasks

- ✕ Slightly bulky for small spaces

- ✕ Manual adjustments needed for complex profiles

| Power | 800W |

| Soldering Area | 180 x 235 mm |

| Temperature Range | 100℃ – 350℃ |

| Cycle Time | 1-8 minutes |

| Temperature Control | Microcomputer automatic control with memory function |

| Application Compatibility | Suitable for various PCB packages including CHIP, SOP, PLCC, QFP, BGA |

The first time I unboxed the Reflow Soldering Station T962, I was impressed by its solid build and compact size. The infrared heating element felt surprisingly robust, and the spacious 180 x 235 mm area immediately made me think about all the projects I could tackle.

Once I powered it up, the microcomputer control really stood out. I loved how easy it was to set the temperature and cycle time—no fuss, just smooth, automatic operation.

During my first soldering run, the rapid infrared heat melted solder quickly and evenly, thanks to the uniform temperature fan. No cold spots or uneven heating here.

The memory function proved handy when switching between different tasks. Storing up to eight temperature profiles meant I could quickly adapt for various PCB types without fiddling with settings each time.

The forced heating and cooling feature also sped up my workflow, especially when I needed to do quick rework or cooling for delicate components.

This oven isn’t just for soldering; its wide versatility shines through. I used it for drying, curing adhesives, and even minor circuit board repairs, and it handled all with ease.

The high power—800W—gives confidence that even larger or double-layer boards can be processed efficiently.

Overall, this reflow oven feels like a reliable partner for hobbyists and small-scale projects. It’s straightforward to operate, precise, and versatile enough to grow with your skills.

For anyone looking to step up their soldering game, this could be a game-changer.

What Is a Hobbyist Reflow Oven and How Does It Work?

A hobbyist reflow oven is a specialized oven used for soldering electronic components onto printed circuit boards (PCBs) through a process called reflow soldering. This method utilizes heat to melt solder paste, connecting components to the board securely.

The definition aligns with the information provided by the IPC, a global trade association for the electronics industry, which underscores the importance of reliable soldering techniques in manufacturing.

A hobbyist reflow oven operates by applying controlled heat to the PCB, enabling the solder paste to melt and create a permanent bond as it cools. These ovens typically feature programmable temperature profiles, ensuring optimal heating cycles for different solder materials and component sizes.

The Electronics Industry Association (EIA) describes reflow soldering as an essential process in electronics assembly, highlighting its efficiency in mass production and versatility for small-scale, hobbyist projects.

Key factors influencing the need for hobbyist reflow ovens include the rise of DIY electronics, increased accessibility of kits, and the shift towards surface-mount technology (SMT) in modern electronics, which often necessitates precise soldering capabilities.

According to market research, the global solder paste market, which is closely linked to reflow soldering, is estimated to grow at a rate of 5.1% annually, indicating a sustained interest in hobbyist electronics.

Hobbyist reflow ovens enable enthusiasts to create reliable electronics, fostering innovation and creativity. They also support environmental sustainability by allowing individuals to repair and recycle electronic devices rather than discard them.

Socially, these ovens encourage community building among hobbyists and makers, leading to knowledge sharing and collaboration. Economically, they can reduce costs for small-scale electronics production.

Examples include users repairing vintage electronics or building custom devices. These activities not only promote sustainability but also enhance technical skills among hobbyists.

To address challenges in hobbyist electronics assembly, experts recommend safety measures such as proper ventilation, and the use of high-quality materials to ensure durable connections.

Strategies such as investing in training workshops, utilizing open-source design tools, and leveraging online resources can help hobbyists maximize their use of reflow ovens while fostering a supportive community.

What Are the Key Benefits of Using a Hobbyist Reflow Oven?

The key benefits of using a hobbyist reflow oven include improved soldering quality, increased efficiency, and greater control over the soldering process.

- Improved soldering quality

- Increased efficiency

- Greater control over the soldering process

- Versatility in circuit board design

- Consistency in results

Using a hobbyist reflow oven has multiple advantages for electronics enthusiasts.

-

Improved Soldering Quality: Improved soldering quality occurs because reflow ovens apply uniform heat. This process allows solder to melt evenly and bond components securely. High-quality solder joints prevent electrical failures and enhance the overall durability of the circuit board. A study by the IPC (Institute of Printed Circuits) in 2021 highlighted that reflow soldering significantly reduces defects compared to hand soldering methods.

-

Increased Efficiency: Increased efficiency is achieved due to faster soldering cycles. Hobbyist reflow ovens can heat multiple components at once, reducing the time spent on assembly. This speed allows makers to work on multiple projects or scale up production for small runs. Research from the IEEE in 2020 indicated that using a reflow oven can cut soldering time in half compared to traditional methods.

-

Greater Control Over the Soldering Process: Greater control over the soldering process comes from adjustable temperature profiles. Users can set specific heating and cooling rates, optimizing the process for various solder types and components. A 2022 study at MIT found that precise temperature settings in reflow ovens lead to better thermal management, reducing the risk of damage to sensitive components.

-

Versatility in Circuit Board Design: Versatility in circuit board design is evident as reflow ovens accommodate surface-mount technology (SMT) as well as through-hole components. This flexibility allows hobbyists to experiment with different layouts and designs without being limited by soldering methods. According to a 2019 report by PCB Design Magazine, modern reflow ovens support a wide array of component sizes, making them ideal for innovative projects.

-

Consistency in Results: Consistency in results is achieved due to the automated nature of reflow ovens. Each soldering cycle can yield the same quality, minimizing variability associated with manual techniques. The amount of rework needed is generally lower, which saves time and resources. A comparative study published by Electronics Weekly in 2021 illustrated that reflow soldering methods lead to fewer failed connections compared to hand-soldered joints.

What Essential Features Should You Look For in a Hobbyist Reflow Oven?

When selecting a hobbyist reflow oven, consider essential features such as precision control, size compatibility, heating uniformity, and additional functionalities.

- Precision Temperature Control

- Size Compatibility

- Heating Uniformity

- User Interface

- Safety Features

- Profile Recording

- Price and Warranty Options

The following sections will elaborate on these essential features.

-

Precision Temperature Control: Precision temperature control in a hobbyist reflow oven ensures that the device can accurately manage heating profiles. This control is critical for soldering components without causing damage. A well-designed oven should maintain specific temperatures within ±1°C to produce consistent results. Many hobbyist users report better solder connections and fewer defects with precise control features.

-

Size Compatibility: Size compatibility refers to the oven’s ability to accommodate various PCB (Printed Circuit Board) dimensions. Hobbyists should choose an oven that can handle both small and larger boards, ensuring versatility. Common sizes for hobbyist projects include boards measuring up to 300mm x 300mm. Some ovens, like the Reflow R1, support larger dimensions, attracting users who work on custom designs.

-

Heating Uniformity: Heating uniformity relates to even heat distribution throughout the oven. This attribute prevents hotspots that can ruin soldering jobs. Quality reflow ovens use multiple heating elements to enhance uniformity. User reviews note significant improvements in solder joint quality when ovens provide consistent heat.

-

User Interface: A user-friendly interface simplifies operation, making it accessible even for beginners. Functions like preset profiles and touchscreen control significantly enhance usability. A survey of hobbyists indicates that those who prefer intuitive features often report higher satisfaction levels with their devices.

-

Safety Features: Safety features are essential to prevent accidents during operation. Many hobbyist reflow ovens come with automatic shutoff, over-temperature protection, and cool-down settings. These features are beneficial for users who prioritize safety while tinkering with electronics in home environments.

-

Profile Recording: Profile recording functionality allows users to save and replicate successful heating profiles. This feature is crucial for achieving consistent results across multiple solder jobs. By recording those profiles, hobbyists can ensure that they do not have to constantly adjust settings for similar boards in the future.

-

Price and Warranty Options: Price and warranty options play a significant role in the selection process. Hobbyists often weigh the initial investment against potential long-term benefits. Many manufacturers offer warranties ranging from one to three years, which can indicate reliability while helping users manage costs effectively.

These essential features provide a comprehensive understanding of what to consider when selecting a hobbyist reflow oven.

Which Are the Top Automatic Desktop Reflow Ovens for Hobbyists?

The top automatic desktop reflow ovens for hobbyists include the following:

- Quick 850SD

- Weller WHA900

- T962A

- Thermaltronics TMT-900

- Hakko FR-301

The selection of a reflow oven can depend on budget, available features, and user experience. Some ovens are simple and affordable, while others offer advanced features for extensive hobby projects.

-

Quick 850SD: The Quick 850SD is highly regarded for its precision and consistency. It features a digital control system for temperature settings and has a compact design suitable for small workspaces. This oven can handle a variety of PCB sizes and is known for its user-friendly interface. Hobbyists appreciate its reliable performance and relatively quick heating times.

-

Weller WHA900: The Weller WHA900 is favored for its durable construction and ability to maintain stable temperatures. It includes programmable settings which allow users to create custom profiles for different soldering jobs. Its strong brand reputation and robust design make it a preferred choice among hobbyists who value reliability in their work.

-

T962A: The T962A is an entry-level model that is popular among beginners. It offers a straightforward design and basic functionalities without requiring a large investment. The oven heats evenly and is suitable for most small to medium soldering projects. However, it lacks advanced temperature profiling features, which may limit its use for more complex tasks.

-

Thermaltronics TMT-900: The Thermaltronics TMT-900 stands out for its innovative features, including a closed-loop control system. This feature ensures accurate temperature control by adjusting the heat in real time. Its versatility can accommodate various PCB sizes and designs. Users appreciate its consistent results, making it a great choice for detailed hobbyist projects.

-

Hakko FR-301: The Hakko FR-301 is known for its ergonomic design and performance efficiency. It is suitable for both professional and hobbyist use. Its features include adjustable temperature settings and a fast heat-up time. Users often find it easy to operate and appreciate its capability to handle diverse soldering tasks.

Selecting the right reflow oven can significantly impact the quality and efficiency of soldering projects. Consideration of factors like budget, specific project requirements, and personal experience level plays a crucial role in this decision.

Which Professional PCB Kits Best Complement a Hobbyist Reflow Oven?

The best professional PCB kits that complement a hobbyist reflow oven typically include items that support efficient assembly and soldering processes.

- Solder Paste

- PCB Design Software

- Stencil Kits

- High-Quality Components

- Thermal Profiling Equipment

- Inspection Tools

When selecting PCB kits, it’s essential to consider their compatibility and how well they enhance the reflow oven’s capabilities.

-

Solder Paste:

Solder paste is a mixture of solder powder and flux used to attach components to PCBs. It enhances the soldering process by ensuring proper adhesion during reflow. Lead-free solder paste is often preferred due to regulatory concerns. Many hobbyists find products like Kester or Amtech to be reliable choices based on performance and ease of use. -

PCB Design Software:

PCB design software allows hobbyists to create custom circuit boards before manufacturing. Software like KiCAD or Eagle provides tools to design and generate the necessary files for PCB production. These applications often include libraries for components, making the design process easier. Hobbyists emphasize the importance of user-friendly interfaces and features that streamline the design process. -

Stencil Kits:

Stencil kits are used to apply solder paste accurately onto the PCBs. These kits typically come with a metal or mylar stencil and a template for alignment. Precision in applying solder paste is crucial for achieving quality solder joints. Many hobbyists recommend investing in a laser-cut stencil for optimal accuracy and reduced waste. -

High-Quality Components:

Using high-quality components ensures the reliability and longevity of the assembled PCBs. Hobbyists often prefer sourcing components from reputable suppliers like Digi-Key or Mouser. Components, such as capacitors and resistors, should meet their specifications to ensure proper function and performance in final products. -

Thermal Profiling Equipment:

Thermal profiling equipment helps monitor the temperature over time during the reflow process. This data ensures that the solder paste reaches the necessary temperatures for melting and bonding components. Hobbyists using thermal profiling tools often report improved solder joint quality and consistency, reducing defects. -

Inspection Tools:

Inspection tools play a critical role in verifying the quality of solder joints and component placements. Tools like magnifying glasses, visual inspection cameras, or automated optical inspection (AOI) systems can help hobbyists check for errors post-reflow. Many enthusiasts suggest that investing in good inspection tools enhances overall project success and reduces failure rates.

What Do Users Say About Their Experiences with Hobbyist Reflow Ovens?

Users generally report mixed experiences with hobbyist reflow ovens, highlighting both positive aspects and challenges.

- Ease of Use

- Cost Efficiency

- Temperature Control

- Quality of Soldering

- Size and Portability

- Learning Curve

- Reliability and Consistency

- Customer Support

Users express their experiences in various ways based on these aspects.

-

Ease of Use: Hobbyist reflow ovens are often praised for their straightforward operation. Users appreciate the simple design and user-friendly controls. For instance, many models feature preset temperature profiles, allowing beginners to achieve good results without deep technical knowledge.

-

Cost Efficiency: Many hobbyists find these ovens cost-effective compared to professional alternatives. Reviews frequently mention that they deliver acceptable quality at a fraction of the price of industrial-grade equipment. A common sentiment is that they are perfect for small projects or prototyping.

-

Temperature Control: Temperature control is a crucial aspect for users. Some models come with precise controls and sensors, leading to better soldering results. However, other users highlight inconsistencies in temperature settings, leading to uneven solder joints.

-

Quality of Soldering: Users often express satisfaction with the soldering quality achieved. Positive feedback usually indicates that reflow ovens produce solder joints comparable to hand soldering. However, some users have experienced issues with cold solder joints, particularly when using incompatible solder materials.

-

Size and Portability: Many hobbyists appreciate the compact size of these ovens. Users report that their lightweight nature makes them easy to store and transport. However, others note that limited internal space can restrict batch sizes, requiring multiple runs for larger projects.

-

Learning Curve: The learning curve is a common theme among users. Novices often find initial operation confusing but gradually adapt. Experienced users highlight the importance of understanding profiles and setups to maximize their oven’s potential.

-

Reliability and Consistency: Users’ opinions on reliability vary. Some report consistent performance, whereas others have encountered malfunction issues, including heating failures or uneven hot spots. These inconsistencies can impact the final product, causing frustration for some users.

-

Customer Support: Customer support experiences differ among users. Some report quick and helpful responses from manufacturers, enhancing their overall experience. Conversely, others express dissatisfaction with the support received, citing slow response times and lack of resolution for issues.

These insights collectively reflect a diverse range of experiences and opinions on the usability and performance of hobbyist reflow ovens.

How Can You Maintain and Optimize Your Hobbyist Reflow Oven for Best Performance?

To maintain and optimize your hobbyist reflow oven for best performance, focus on regular cleaning, proper calibration, temperature profiling, and attentive usage practices.

Regular cleaning: Keeping the oven clean prevents residue build-up. Dust and solder paste can affect performance. Clean the heating elements and interior surfaces with a soft cloth. Ensure no spills of solder paste create a mess inside. Frequent cleaning enhances heat transfer efficiency.

Proper calibration: Calibration is essential to ensure accurate temperature readings. Use a thermocouple or infrared thermometer to measure the actual temperature during operation. Adjust the oven settings to match the desired profile. Regular calibration helps maintain consistent heating and prevents component damage.

Temperature profiling: Create and use temperature profiles for different types of solder and components. The temperature profile should consist of the preheat, soak, reflow, and cooling stages. A study by McDonnel et al. (2021) emphasizes that optimal reflow profiles lead to better solder joint integrity. Following the right profile prevents issues like cold solder joints or component damage.

Attentive usage practices: Monitor and adjust the oven settings based on specific materials. Pay attention to the size and type of components being soldered. Larger components may require longer heating times. Avoid overcrowding the oven to ensure even heat distribution.

By focusing on these areas, you can enhance the reliability and efficiency of your hobbyist reflow oven.

Related Post: